Xinhui Valve Co., Ltd. is a high-tech chemical valve manufacturer integrating R&D, production, sales and service, specializing in the production of power station valves, high temperature and high pressure valves, forged ball valves, three-way ball valves, pigging valves, slurry valves, petrochemical valves Equipment and other products, valve varieties are complete, the first in the industry to pass ISO9001, CE international certification, etc., and put into use in various fields, users highly recognized our company’s valve products.

1. Inspection and test items of various types of valves |

Valve class | gate valve | Globe valve | throttle valve | Ball valve | Butterfly valve | Diaphragm valve | Plug valve | check valve |

Check and test items | shell body strength | √ | √ | √ | √ | √ | √ | √ | √ |

sealing performance | √ | √ | - | √ | √ | √ | √ | √ |

Upper sealing performance① | √ | √ | - | - | - | - | - | - |

quality of castings | √ | √ | √ | √ | √ | √ | √ | √ |

Continuous trouble-free opening and closing operation | √ | √ | - | √ | √ | √ | √ | - |

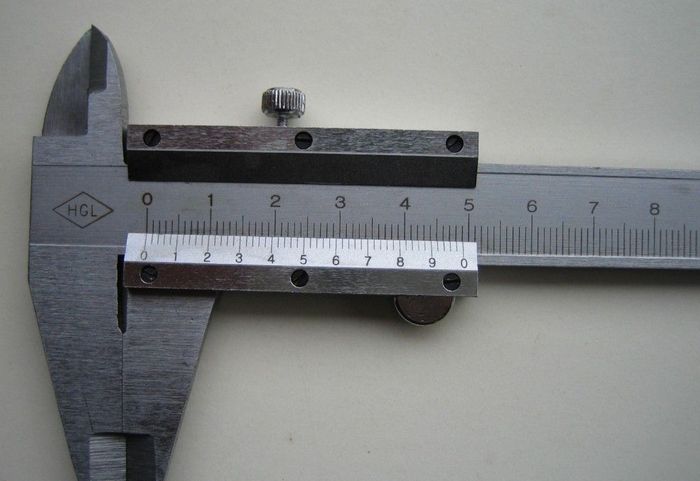

Minimum valve body wall thickness | √ | √ | √ | √ | √ | √ | √ | √ |

Inner cavity cleanliness | √ | √ | √ | √ | √ | √ | √ | √ |

Maximum opening and closing torque | √ | √ | - | √ | √ | √ | √ | - |

Anti-static test | - | - | - | √ | - | - | - | - |

Fire resistance test ② | - | - | - | √ | - | - | - | - |

Parts inspection | √ | √ | √ | √ | √ | √ | √ | √ |

Flow test | √ | √ | √ | √ | √ | √ | √ | √ |

① Valves with upper sealing performance requirements need to be tested for upper sealing

② Other valves can also be tested for fire resistance if they have fire resistance requirements

2. Inspection and test items of safety valve, pressure reducing valve and steam trap |

Valve class | safety valve | pressure reducing valve | Steam Traps Valves |

Inspection and test items | shell body test | shell body test | shell body test |

sealing test | Pressure regulating performance | action performance |

Set pressure deviation | pressure characteristics | Thermal condensation junction water Displacement |

discharge pressure | Traffic characteristics | Air leakage volume |

Turn on height | Continuous trouble-free opening and closing operation | Exhaust Air Capability |

Mechanics Characteristics | sealing performance | Continuous trouble-free opening and closing operation |

action repetitiveness | flow | quality of castings |

Opening and closing pressure difference | quality of castings | highest working pressure |

Displacement | Inner cavity cleanliness | Minimum working pressure |

quality of castings | - | Maximum working back pressure |

Inner cavity cleanliness | - | Maximum subcooling and minimum subcooling |

- | - | Inner cavity cleanliness |

- | - | - |

- | - | Withstand voltage test① |

①The withstand pressure test is a test of the trap parts that are subjected to external pressure (such as the ball of the floating ball trap, etc.)

3. Factory test and type test items of safety valve, pressure reducing valve and steam trap |

safety valve | pressure reducing valve | Steam Traps Valves |

Test item | out of factory | Type | Test item | out of factory | Type | Test item | out of factory | Type |

shell body strength | √ | √ | shell body strength | √ | √ | shell body strength | √ | √ |

sealing test | √ | √ | sealing test | √ | √ | action performance | √ | √ |

set pressure | √ | √ | Pressure regulating performance | √ | √ | Minimum working pressure | - | √ |

emission pressure | √ | √ | Traffic Features | - | √ | highest working pressure | - | √ |

Opening pressure deviation | - | √ | pressure characteristics | - | √ | Maximum working back pressure | - | √ |

Turn on height | - | √ | flow | - | √ | Exhaust Air Capability | - | √ |

mechanical features | - | √ | Continuous running test | - | √ | Maximum subcooling and minimum subcooling | - | √ |

Displacement | - | √ | - | - | - | Air leakage volume | - | √ |

- | - | - | - | - | - | Thermal condensation junction water Displacement | - | √ |

4. Key items and main items for valve quality grade assessment ①② |

Valve class | gate valve | Globe valve | throttle valve | Ball valve | Butterfly valve | Diaphragm valve | Plug valve | check valve |

shell body test | △ | △ | △ | △ | △ | △ | △ | △ |

sealing performance test | △ | △ | - | △ | △ | △ | △ | △ |

Upper sealing test ③ | △ | △ | - | - | - | - | - | - |

quality of castings | △ | △ | △ | △ | △ | △ | △ | △ |

Continuous trouble-free opening and closing operation | △ | △ | - | △ | △ | △ | △ | - |

Minimum valve body wall thickness | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Inner cavity cleanliness | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Maximum opening and closing torque | - | ○④ | - | - | ○ | - | - | - |

gate-Wear-Margin | ○ | - | - | - | - | - | - | - |

Flange dislocation during non-processing | ○ | - | - | - | - | - | - | - |

valve body lining material | - | - | - | - | - | ○⑤ | - | - |

Diaphragm Performance | - | - | - | - | - | ○ | - | - |

①△ is the key item

②○ is the main item

③ Valves with upper sealing performance requirements should be tested for upper sealing

④High pressure balance globe valve has this requirement

⑤Applicable to lined diaphragm valve

5. Key items and main items for quality grade assessment of safety valves, pressure reducing valves and steam traps①② |

safety valve | pressure reducing valve | Steam Traps Valves |

shell body test | △ | shell body strength | △ | shell body test | △ |

sealing test | △ | Pressure regulating performance | △ | action performance | △ |

Opening pressure deviation | △ | pressure characteristics | △ | Withstand voltage test④ | △ |

discharge pressure | △ | Traffic Features | △ | Thermal condensation junction water Displacement | △ |

Turn on height | △ | quality of castings | △ | Air leakage volume | △ |

mechanical features | △ | Continuous trouble-free opening and closing operation | △ | Exhaust Air Capability | △ |

action repetitiveness | △ | sealing performance | ○ | quality of castings | △ |

Opening and closing pressure difference | △ | Inner cavity cleanliness | ○ | Continuous trouble-free opening and closing operation | △ |

Spring ③ | △ | - | - | highest working pressure | ○ |

quality of castings | △ | - | - | Minimum working pressure | ○ |

Inner cavity cleanliness | ○ | - | - | Maximum working back pressure | ○ |

Displacement | ○ | - | - | maximum subcooling | ○ |

- | - | - | - | Inner cavity cleanliness | ○ |

- | - | - | - | Pouring-buckle residual amount⑤ | ○ |

- | - | - | - | Residual amount after welding repair⑥ | ○ |

①△ is the key item

②○ is the main item

③Suitable for spring type safety valve

④For trap parts that are subject to external pressure, such as the ball of a floating ball steam trap, etc.

⑤, ⑥ Applicable to mechanical type steam trap with closed float