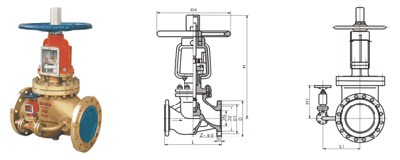

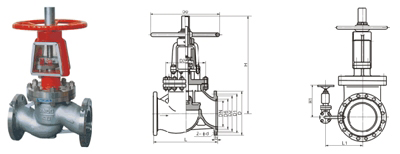

Oxygen Globe Valve

Oxygen Globe Valve

Oxygen globe valve belongs to the forced sealing type valve, so when the valve is closed, pressure must be applied to the valve flap to force the sealing surface not to leak. When the medium from below the valve flap into the valve six, the operating force to overcome the resistance, is the friction of the valve stem and packing and the pressure generated by the medium of the thrust, the force to close the valve is greater than the force to open the valve, so the diameter of the valve stem should be large, otherwise it will occur the stem top bending of the fault.

Technical Specifications

Structure than the gate valve is simple, manufacturing and maintenance are more convenient.

The sealing surface is not easy to wear and abrasion, good sealing, opening and closing of the valve flap and the valve body sealing surface without relative sliding, so the wear and abrasion are not serious, good sealing performance, long service life.

When opening and closing, the flap stroke is small, so the height of the globe valve is smaller than the gate valve, but the length of the structure is longer than the gate valve.

Opening and closing torque is large, opening and closing more laborious, opening and closing time principal.

Fluid resistance, because the valve body media channel is more zigzag, fluid resistance, power consumption.

Medium flow direction Nominal pressure PN ≤ 16MPa, generally used downstream, the media from the valve flap upward direction; nominal pressure PN ≥ 20MPa, generally used countercurrent, the media from the valve flap upward downward flow. To increase the sealing energy. When used, the cut-off valve medium can only flow in one direction, can not change the direction of flow.

Full open valve flap is often subject to erosion.

Main Parts Materials:

Body | Cover | Flap:

Copper Alloy | Cast Chrome Nickel Titanium Stainless Steel

Stem:

Chrome Nickel Stainless Steel

Stem Nut:

Bronze

Brand

Jitai

Customized Processing

Yes

Material

Copper

Applicable Medium

Oxygen

Pressure Environment

Atmospheric

Operating Temperature

Ordinary Temperatures

Flow Direction

Commutation

Driving Method

Manually Operated

Parts And Accessories

Valve Body

Morphological

Other

Sealing Form

Other

Shape

Medium Size

Design Standard:

Design And Manufacture:GB12235

Flange Size:GB9113

Structure Length:GB12221

Inspection And Experiment:GB/T13927

Operating Principle:

When the handwheel is turned clockwise, the valve stem moves downward, the valve flap drops to make the sealing surface close, and cut off the access. Reversal is open, the valve stem to the highest point on the sealing effect.

This valve adds an upper seal. In the open state of the valve, with the packing together with two sealing effect, and the packing has a certain degree of protection.

This valve adopts nylon products as sealing surface, packing for soft molding packing, the upper seal is also a soft material, sealing performance is better.

1.6MPa Connection Size And Weight:

| DN | L | D | D1 | D2 | b | f | Z-d | H | H1 | DO | L1 | 重量(kg) |

| 15 | 130 | 95 | 65 | 45 | 14 | 2 | 4~14 | 240 | 100 | 6 | ||

| 20 | 150 | 105 | 75 | 55 | 14 | 2 | 4~14 | 270 | 100 | 8 | ||

| 25 | 160 | 115 | 85 | 65 | 14 | 2 | 4~14 | 270 | 125 | 10 | ||

| 32 | 180 | 135 | 100 | 78 | 16 | 2 | 4~18 | 280 | 160 | 14 | ||

| 40 | 200 | 145 | 110 | 85 | 16 | 3 | 4~18 | 350 | 160 | 20 | ||

| 50 | 230 | 160 | 125 | 100 | 16 | 3 | 4~18 | 400 | 320 | 35 | ||

| 65 | 290 | 180 | 145 | 120 | 18 | 3 | 4~18 | 530 | 360 | 50 | ||

| 80 | 310 | 195 | 160 | 135 | 20 | 3 | 8~18 | 560 | 400 | 65 | ||

| 100 | 350 | 215 | 180 | 155 | 20 | 3 | 8~18 | 618 | 450 | 80 | ||

| 125 | 400 | 245 | 210 | 185 | 99 | 3 | 8~18 | 675 | 450 | 106 | ||

| 150 | 480 | 280 | 240 | 210 | 24 | 3 | 8~23 | 743 | 560 | 125 | ||

| 200 | 600 | 335 | 295 | 265 | 26 | 3 | 12~23 | 850 | 640 | 254 | ||

| 250 | 650 | 405 | 355 | 320 | 30 | 3 | 12~25 | 975 | 270 | 720 | 380 | 418 |

| 300 | 750 | 460 | 410 | 375 | 30 | 4 | 12~25 | 1115 | 270 | 800 | 415 | 502 |

| 400 | 950 | 580 | 525 | 485 | 36 | 4 | 16-30 | 1380 | 280 | 900 | 465 | 980 |

| 450 | 1050 | 640 | 585 | 545 | 40 | 4 | 20-30 | 1530 | 350 | 495 | 1200 | |

| 500 | 1150 | 705 | 650 | 608 | 44 | 4 | 20-34 | 1700 | 400 | 525 | 1300 |

Cause Analysis:

Rust, dust, welding slag in the pipeline and the pipeline wall or valve friction to generate high temperature combustion.

This situation is related to the type of impurities, particle size and air velocity, iron powder is easy to burn with oxygen, and the finer the particle size, the lower the ignition point; the faster the gas speed, the more likely to burn.

Pipes or valves in the presence of grease, rubber and other low-flammability substances, in the local high temperature ignition.

Specifications:

Structure than the gate valve is simple, manufacturing and maintenance are more convenient.

The sealing surface is not easy to wear and abrasion, good sealing, opening and closing of the valve flap and the valve body sealing surface without relative sliding, so the wear and abrasion are not serious, good sealing performance, long service life.

When opening and closing, the flap stroke is small, so the height of the globe valve is smaller than the gate valve, but the length of the structure is longer than the gate valve.

Opening and closing torque is large, opening and closing more laborious, opening and closing time principal.

Fluid resistance, because the valve body media channel is more zigzag, fluid resistance, power consumption.

Medium flow direction Nominal pressure PN ≤ 16MPa, generally used downstream, the media from the valve flap upward direction; nominal pressure PN ≥ 20MPa, generally used countercurrent, the media from the valve flap upward downward flow. To increase the sealing energy. When used, the cut-off valve medium can only flow in one direction, can not change the direction of flow.

Full open valve flap is often subject to erosion.

Your quest for reliable and efficient ball valves ends here with Reliable Ball Valve Suppliers. We are a team of dedicated ball valve manufacturers who take pride in our ability to deliver top-notch products. Our custom ball valves service ensures that every valve is made to your exact specifications, offering a perfect fit for your unique requirements.

GET A QUOTE FREE

Contact Us

Since 2008, we have been serving in the industry for 15 years. Whether it’s300 series stainless steel, super duplex steel, nickel based alloy materials,trust us to provide you with a relaible solution!

We can be at your service within 24

hours. You also can send email to us: info@kaysuns.com