Oxygen Check Valve

Oxygen Check Valve

Oxygen check valve is suitable for oxygen pipeline network and other systems as a check valve, play the role of intercepting and stopping the flow, such as oxygen-enriched systems to prevent the backflow of cold air, sputtering slag furnace to prevent nitrogen, oxygen and each other string. Check valves are generally applicable to clean media, should not be used for solid particles and viscosity of the media.

Technical Specifications

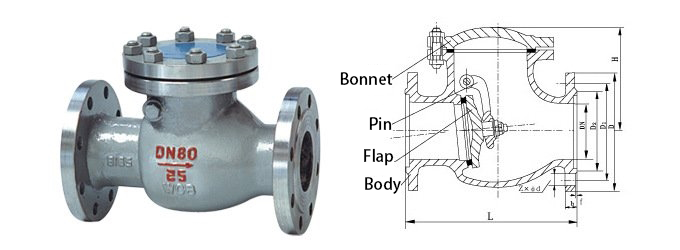

This product consists of valve body, valve cover, valve plate and other components, the medium from one end into the valve plate rise, the media flow; when the media pressure disappears or the export pressure is greater than the import pressure, the valve plate itself down to close the channel, and play the role of check. Valve main parts are made of silicon brass, with good fire resistance. Check valve is generally applicable to clean media, should not be used for solid particles and viscosity of the medium.

Customized Processing

Yes

Connection

Flange

Material

Carbon Steel | Stainless Steel | Brass | Cast Iron

Cast Copper | Ductile Iron | Alloy Steel | Plastic

Copper Alloy | Ceramic | PPR | PVC | Fluorine Lining | Copper

Applicable Medium

Water | Steam | Oil |Air | Ammonia | Nitrogen

Oxygen | Hydrogen | Liquefied Gas | Coal Gas

Dusty Gases | Weak Acid And Alkali Media

All Kinds Of Highly Corrosive Chemical Media

Pressure Environment

Atmospheric

Operating Temperature

Ordinary Temperatures

Driving Method

Manually Operated

Parts And Accessories

Sphere

Morphological

Other

Type

Pilot Operated

Sealing Form

Hard Seal

Kind

Other

Features And Benefits

Oxygen check valve consists of valve body, valve cover, valve plate and other components, the medium from one end into the valve plate rise, the media flow; when the media pressure disappears or the export pressure is greater than the import pressure, the valve plate itself down to close the channel, to play the role of check. The main parts of the valve are made of silicon brass, with good flame retardant properties, suitable for oxygen pipeline network and other systems as a one-way valve, play the role of intercepting and checking, such as oxygen-enriched systems to prevent the backflow of cold air, sputtering slag furnace to prevent nitrogen, oxygen and each other string. Check valves are generally applicable to clean media, should not be used for solid particles and viscosity of the media.

The valve is generally applicable to clean medium, not suitable for solid particles and viscosity of the medium.

The liner of the valve is made of special material with good abrasion resistance and small friction coefficient, with flexible and reliable action and excellent sealing performance.

The valve has a novel structure, small size, light weight, low fluid resistance, smooth opening and closing, long service life, oil pressure, slow closure is not affected by the medium, and has a good energy-saving effect and other characteristics.

The valve can be installed at the outlet of water pump, which can avoid water hammer, water percussion sound and destructive impact, and achieve the purpose of preventing backflow and protecting equipment.

| Model | PN (MPa) | DN (mm) | Size(mm) | Weight (Kg) | |||||||

| L | D | D1 | D2 | b | Z-d | D3 | H | ||||

| HY44W (16P) HY44W (16T) | 1.6 | 40 | 200 | 145 | 110 | 88 | 20 | 4-18 | 145 | 103 | 15.2 |

| 50 | 230 | 160 | 125 | 102 | 20 | 4-18 | 185 | 160 | 21.3 | ||

| 65 | 290 | 180 | 145 | 122 | 22 | 8-18 | 215 | 175 | 28.1 | ||

| 80 | 310 | 195 | 160 | 133 | 22 | 8-18 | 235 | 185 | 37.6 | ||

| 100 | 350 | 230 | 180 | 158 | 24 | 8-23 | 270 | 220 | 56.7 | ||

| 125 | 400 | 270 | 210 | 184 | 28 | 8-25 | 375 | 248 | 129 | ||

| 150 | 480 | 300 | 240 | 212 | 30 | 8-25 | 375 | 270 | 129 | ||

| 200 | 550 | 360 | 295 | 268 | 34 | 12-25 | 435 | 350 | 210 | ||

| 250 | 650 | 425 | 355 | 320 | 36 | 12-30 | 515 | 415 | 290 | ||

| 300 | 750 | 485 | 410 | 370 | 40 | 16-30 | 320 | ||||

| 350 | 850 | 550 | 470 | 430 | 44 | 16-34 | 420 | ||||

Your quest for reliable and efficient ball valves ends here with Reliable Ball Valve Suppliers. We are a team of dedicated ball valve manufacturers who take pride in our ability to deliver top-notch products. Our custom ball valves service ensures that every valve is made to your exact specifications, offering a perfect fit for your unique requirements.

GET A QUOTE FREE

Contact Us

Since 2008, we have been serving in the industry for 15 years. Whether it’s300 series stainless steel, super duplex steel, nickel based alloy materials,trust us to provide you with a relaible solution!

We can be at your service within 24

hours. You also can send email to us: info@kaysuns.com