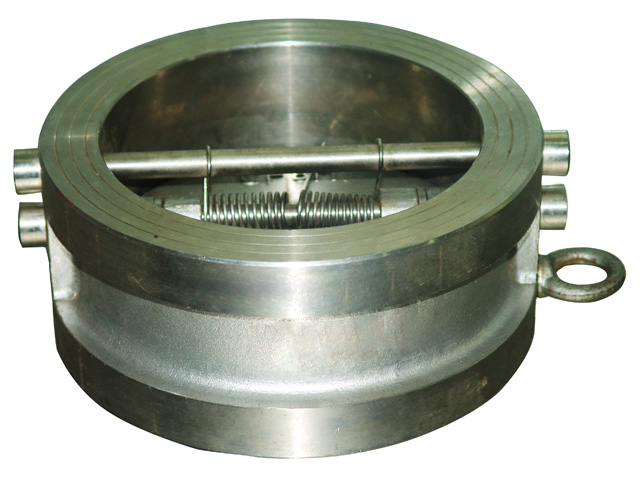

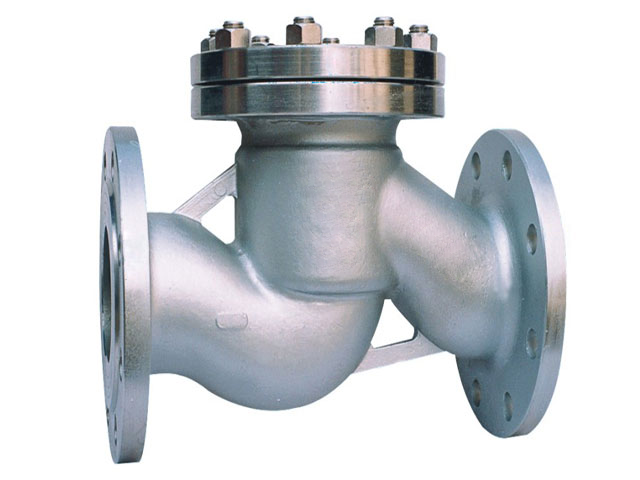

Pressure Seal Check Valve

Pressure Seal Check Valve

The pressure seal check valve is a check valve for high pressure service that utilizes pressure within the system to enhance the sealing effect. Its sealing structure becomes tighter as the pressure within the pipeline increases, preventing backflow and effectively reducing the risk of leakage.

Technical Specifications

Materials:

Body:

Cast Steel:

ASTM A216 WCB, WCC | ASTM A352 Gr. LC3, LCB | ASTM A217 gr.B, C5, C12, WC6, WC9, WC12

Stainless Steel:

ASTM A351 CF8, CF3, CF8M, CF3M, CK20, CG8M, A351 CK3MCuN etc.

Duplex:

A890 Gr.4A, Gr. 6A (SAF2205, 2507 etc.)

Nickel Alloy:

Monel 400 | Inconel 600, 625 | Hastelloy C27, C22, B2 | Incoloy 800/800HT, 825 etc.

Ball:

ASTM A105 w/ENP | ASTM A350 Gr. LF2 w/ENP | ASTM A182 Gr. F316 | ASTM A182 Gr. F316 w/ENP

Stainless Steel | Duplex SS | Nickel Alloy etc.

Seat:

RPTFE | Nylon | Davilon | PEEK | Tek-Fil® | TFM

Stem:

ASTM A479 Type 410 | 17-4PH | XM-19 | ASTM A182 F316 | Stainless Steel | Duplex SS | Nickel Alloy etc.

Caliber Range

1/2“ to 24” | DN15 to DN600

Pressure Range

Class150 to 2500 | PN10 to PN420

Operating Temperature

-29℃ to 560℃ | -20.2℉ to 1040℉

Connection

RF | RTJ | BW

Design Standard

BS1868 | ASME B16.34 | GB/T 12235 | JB/T3595

Temperature Range

-60℃ to 200℃ | -76℉ to 392℉

Features And Benefits

Pressure seal check valves are mainly used in fossil fuel power plants under high temperature and high pressure.Compared with bolted valves, these valves provide absolute safety sealing at the bonnet joint, and therefore provide closer service for maintenance of the valves under high temperature and high pressure environments.

This is an automatic valve that opens and closes the valve by the thrust generated by the flow of the medium in the pipeline, the main function of which is to prevent the backflow of the medium in the pipeline.

Single Sealing Surface Structure

There is only one sealing surface between the valve body and the valve plate, which simplifies the structure and ensures sealing stability.

Stellite Surfacing Sealing Surface

The valve seat sealing surface is surfaced with Stellite material, which enhances wear resistance and corrosion resistance, and prolongs service life.

Easy Production And Maintenance

Simplified design for easy production and maintenance, reducing downtime.

Flexible Graphite Packing

Equipped with flexible graphite packing, adapting to high temperature and high pressure environment, ensuring reliable sealing.

Leak-free Bonnet Connection

The bonnet connection is designed to be leak-free, effectively preventing leakage of medium and improving safety.

Bypass Design

With bypass function, it is convenient for flow adjustment and maintenance operation.

Shock Absorbing Cylinder Design

Equipped with shock absorbing cylinder to reduce vibration and noise and enhance the comfort of use.

Your quest for reliable and efficient ball valves ends here with Reliable Ball Valve Suppliers. We are a team of dedicated ball valve manufacturers who take pride in our ability to deliver top-notch products. Our custom ball valves service ensures that every valve is made to your exact specifications, offering a perfect fit for your unique requirements.

GET A QUOTE FREE

Contact Us

Since 2008, we have been serving in the industry for 15 years. Whether it’s300 series stainless steel, super duplex steel, nickel based alloy materials,trust us to provide you with a relaible solution!

hons von alko can senenat to ueply you in 24 hours.You also can send email to us: info@kaysuns.com